As a seasoned professional with years of experience in the industrial compressed air sector, I've witnessed firsthand how the right compressor technology can transform manufacturing processes, enhance operational efficiency, and reduce long-term costs. For industrial buyers navigating the complex landscape of compressed air solutions, a thorough understanding of screw air compressors is essential for making informed purchasing decisions that align with both immediate requirements and long-term strategic goals.

This comprehensive guide explores the working principles, technological advancements, and practical applications of screw air compressors, with specific focus on oil-free variants that are critical in sensitive manufacturing environments. Whether you're evaluating screw air compressors suppliers, comparing technologies like scroll type air compressors and rotary tooth compressors, or seeking an oil-free compressor technology comparison, these insights will help guide your decision-making process.

Understanding Screw Air Compressor Technology

Screw air compressors represent a significant advancement in compressed air technology, offering reliable performance, energy efficiency, and operational flexibility that meets the demanding requirements of modern manufacturing facilities. These positive displacement machines operate on a simple yet highly effective principle that has revolutionized industrial compressed air production.

At the heart of every screw compressor lies a pair of precisely engineered helical rotors rotating in opposite directions within a specially designed housing. As these rotors turn, air is drawn into the compression chamber through an inlet port. The unique spiral profile of the rotors traps air between their lobes and the compressor housing, gradually reducing volume as it moves along the length of the rotors. This progressive reduction in volume increases air pressure, which is then discharged through an outlet port at the desired pressure level.

The efficiency of this design comes from several key factors. The continuous compression process eliminates the pulsating output of reciprocating compressors, resulting in smoother air delivery and reduced vibration. Minimal clearance between rotors and housing minimizes internal leakage, ensuring most energy input converts directly into compressed air. The rotating components are inherently balanced, reducing wear and extending service life compared to reciprocating designs with their reciprocating masses and numerous moving parts.

Modern screw compressors include advanced design features that further enhance performance. Precision manufacturing techniques ensure rotor profiles optimize efficiency across varying operating conditions. Integrated cooling systems maintain optimal operating temperatures, preventing overheating during extended duty cycles. Variable speed drives have become common, allowing compressors to match output precisely to demand and reduce energy consumption during lower air usage periods.

Oil-Free vs. Oil-Injected Screw Compressors: An Essential Comparison

When evaluating screw air compressor technologies, understanding the fundamental difference between oil-free and oil-injected designs is critical. This distinction has far-reaching implications for performance characteristics, maintenance requirements, and suitability for specific applications.

Oil-injected screw compressors utilize lubricating oil within the compression chamber that serves multiple purposes. This oil acts as a seal between rotating rotors, reducing internal leakage and improving compression efficiency. It also serves as a coolant, absorbing heat generated during compression, and as a lubricant for rotor bearings and other moving components. While this design offers excellent efficiency and relatively lower initial costs, it introduces the challenge of oil contamination in the compressed air stream.

Oil-free screw compressors eliminate oil from the compression chamber entirely. Through precision engineering, these compressors maintain extremely tight tolerances between rotors and housing, removing the need for oil as a sealing medium. Instead of oil lubrication, these compressors typically use specialized dry lubricants or water injection systems to manage heat and reduce friction. The result is compressed air that meets the strictest purity standards, making oil-free compressors indispensable in applications where air quality is paramount.

The decision between oil-free and oil-injected compressors involves careful consideration of several factors. Oil-free models generally cost more initially but offer significant advantages in air quality, reduced maintenance requirements related to oil handling and disposal, and elimination of product contamination risk. For pharmaceuticals, food and beverage processing, electronics manufacturing, and healthcare industries, the premium for oil-free technology is often justified by the critical nature of air quality in production processes.

Oil-injected compressors require more extensive maintenance for oil changes, filtration, and contamination control. They may represent a more economical choice for general manufacturing applications where air purity requirements are less stringent. However, it's essential to factor in long-term costs of oil management, filtration systems, and potential product contamination issues when making this decision.

Comparing Compressor Technologies: Screw vs. Scroll vs. Rotary Tooth

Industrial buyers evaluating compressed air solutions face a fundamental decision regarding compressor technology. Three primary options dominate the market: screw, scroll, and rotary tooth compressors. Each technology offers distinct advantages and limitations that make them better suited for specific applications and operating conditions.

Screw compressors excel in delivering high volumes of compressed air with exceptional energy efficiency and reliability. Their continuous duty cycle capability, minimal vibration, and relatively compact footprint make them ideal for applications requiring consistent compressed air supply at medium to high flow rates. Modern screw compressors typically operate with discharge pressures from 7 to 15 bar (100 to 218 psi), with some specialized models reaching higher pressures for specific industrial processes.

Scroll compressors operate using two interleaving spiral elements—one fixed and one orbiting—to compress air. As the orbiting scroll moves within the fixed scroll, air gets trapped in pockets formed between the two elements and gradually compresses as these pockets move toward the spiral center. This design offers advantages including extremely low noise levels, minimal vibration, and fewer moving parts compared to both screw and reciprocating compressors. Scroll type air compressors are often favored for applications requiring low noise operation and moderate air flow.

Rotary tooth compressors, sometimes called rotary vane compressors, use a cylindrical rotor with sliding vanes that maintain contact with the compressor housing. As the rotor turns, centrifugal force pushes vanes outward, creating compression chambers that decrease in volume as they rotate around the housing. This design offers simplicity, compact size, and relatively low initial cost, making it popular for applications with moderate pressure and flow requirements. When evaluating rotary tooth compressors suppliers, it's important to assess their specific design variations and performance characteristics.

When comparing these technologies for specific applications, several key factors come into play:

Flow Rate Capability: Screw compressors generally offer the highest flow rates, suitable for large-scale industrial applications. Scroll compressors typically serve medium-flow requirements, while rotary tooth designs work best for smaller-scale applications.

Energy Efficiency: Screw compressors, particularly variable speed models, offer excellent efficiency across a wide range of operating conditions. Scroll compressors also demonstrate good efficiency, especially at full load, while rotary tooth designs generally have lower efficiency compared to the other two technologies.

Maintenance Requirements: Scroll compressors typically have the fewest maintenance requirements due to their simple design and minimal moving parts. Screw compressors require regular maintenance but offer extended service intervals compared to many rotary tooth designs.

Noise Levels: Scroll compressors operate at the lowest noise levels, often 10-15 dB(A) quieter than comparable screw compressors. Rotary tooth compressors generally produce moderate noise levels, while screw compressors, despite advancements in sound attenuation, typically require additional noise reduction measures in noise-sensitive environments.

Cost Considerations: Rotary tooth compressors often have the lowest initial cost, followed by scroll compressors, with screw compressors representing the highest initial investment. However, when evaluating total cost of ownership over the equipment lifecycle, the higher efficiency and longer service life of screw compressors often result in lower overall costs for high-demand applications.

Key Considerations for Evaluating Screw Air Compressors Suppliers

For industrial buyers investigating screw air compressors suppliers, a structured evaluation process ensures the selected supplier provides not just a technologically suitable product but also demonstrates reliability, support capabilities, and long-term partnership potential necessary for successful implementation and ongoing operation.

Technical Capability Assessment should form the foundation of any supplier evaluation. This involves verifying the supplier's product range includes screw compressors with the specific performance characteristics required for your application—flow rate, pressure range, energy efficiency ratings, and air quality specifications. Request detailed technical documentation, including performance curves under various operating conditions, to validate claims. A reputable supplier should provide comprehensive data and be transparent about product capabilities and limitations.

Quality Management Systems and Certifications indicate a supplier's commitment to consistent product quality. Look for suppliers with internationally recognized certifications such as ISO 9001 for quality management systems, demonstrating adherence to rigorous quality control processes throughout manufacturing. For oil-free compressors in critical applications, verify additional certifications like ISO 8573-1 for compressed air purity, ASME BPVC for pressure vessel safety, or industry-specific certifications relevant to your sector (such as FDA compliance for pharmaceutical applications).

Manufacturing and Quality Control Processes warrant close examination. Suppliers should clearly articulate their manufacturing processes from component sourcing to final assembly and testing. Inquire about quality control protocols at each production stage and their approach to continuous improvement. A supplier investing in advanced manufacturing technologies and maintaining strict quality control standards is more likely to deliver reliable, consistent products.

Service and Support Capabilities are often overlooked during evaluation but critical for long-term satisfaction. Evaluate the supplier's service network, including availability of factory-trained technicians in your region, response time guarantees for service calls, and spare parts availability. A comprehensive service offering should include preventive maintenance programs, remote monitoring capabilities, and technical support resources. For international suppliers, verify established local support infrastructure to avoid delays in service and support.

Energy Efficiency and Sustainability Initiatives have become important evaluation criteria. Inquire about the supplier's commitment to energy efficiency, including compliance with international standards like IE3 or IE4 motor efficiency ratings, and any additional energy-saving features in their designs. A forward-thinking supplier should provide energy consumption data, efficiency guarantees, and guidance on system optimization to minimize long-term operating costs.

Customer References and Case Studies provide valuable insights into real-world performance. Request references from customers with similar applications or industry backgrounds. Follow up on these references to inquire about experience with the supplier's products, service, and overall partnership. Case studies demonstrating successful implementation, problem-solving capabilities, and measurable results can provide additional confidence in capabilities.

Financial Stability and Longevity considerations help mitigate supplier disruption risk. Evaluate the supplier's financial health, market position, and industry tenure to ensure they'll be a reliable partner throughout your compressed air system's lifecycle. A supplier with strong market position and proven financial stability is more likely to invest in research and development, maintain consistent quality, and provide ongoing product support.

Customization Capabilities may be important if your application has unique requirements. Assess the supplier's willingness and ability to modify standard products or develop custom solutions for specific operational challenges. A supplier with strong engineering capabilities and flexible product development approach can often provide more tailored solutions delivering better long-term value.

By systematically evaluating potential suppliers against these criteria, industrial buyers move beyond simple price comparisons. They make informed decisions based on comprehensive assessment of value, quality, and long-term partnership potential. This approach ensures the selected screw air compressor supplier meets immediate technical requirements and contributes to operational efficiency, reliability, and business success long-term.

Applications and Industry-Specific Considerations

Screw air compressors have become indispensable across diverse industries. Each presents unique requirements and considerations influencing technology selection and supplier evaluation. Understanding how screw compressor technology performs in specific industrial contexts helps industrial buyers make optimal purchasing decisions.

Manufacturing and Automotive Industries represent some of the largest screw air compressor users. In these environments, compressors typically supply air for pneumatic tools, automated production lines, material handling systems, and quality control processes. Key considerations include reliability, continuous duty cycle capability, and energy efficiency, as compressors often operate around the clock. Oil-free models are increasingly preferred in automotive painting and finishing applications to prevent contamination of sensitive surfaces and ensure consistent quality.

Food and Beverage Processing demands high air purity standards to ensure product safety and regulatory compliance. Oil-free screw compressors are essential here to prevent oil contamination in food products or packaging materials. Additionally, compressors for food processing must withstand washdown conditions and meet specific hygiene standards like those outlined by FDA or EU 10/2011 regulations. Material selection—including stainless steel components and food-grade lubricants—becomes critical when evaluating suppliers for these applications.

Pharmaceutical and Healthcare Industries require compressed air meeting even more stringent purity standards, often necessitating Class 0 oil-free air as defined by ISO 8573-1. Screw compressors used in pharmaceutical manufacturing must comply with Good Manufacturing Practices (GMP) and may require additional filtration and drying systems to remove particulate matter, moisture, and microbial contaminants. For medical applications like respiratory equipment or surgical tools, compressors must meet specific medical device standards, including ISO 13485 for quality management systems and ISO 8573-1 Class 1 or higher for air quality.

Electronics and Semiconductor Manufacturing presents unique challenges due to microelectronic components' extreme sensitivity to particulate contamination and static electricity. Oil-free screw compressors play a critical role in cleanroom environments where even minute oil particles can cause product defects and yield losses. Beyond oil-free operation, compressors for electronics manufacturing often require specialized drying systems to achieve extremely low dew points (typically -40°C or lower) to prevent moisture-related production issues.

Energy and Power Generation industries use screw compressors in various applications from power plant instrumentation and control systems to pipeline maintenance and carbon capture processes. In these demanding environments, reliability and durability are paramount since unplanned downtime can have significant financial implications. Compressors must often operate in harsh conditions—high temperatures, dusty environments, or hazardous locations—requiring specialized designs and robust construction.

Chemical and Petrochemical Industries need compressors that handle potentially corrosive or hazardous environments while maintaining strict safety standards. Screw compressors for these applications must be constructed from chemical-resistant materials and designed to prevent process gas leakage. Compliance with industry-specific safety standards from API (American Petroleum Institute) or ATEX for explosive atmospheres is often mandatory.

Construction and Mining applications demand portable screw compressors delivering high air volumes for pneumatic tools, drilling operations, and material conveying in remote locations. These compressors must be ruggedly constructed to withstand harsh operating conditions including extreme temperatures, vibration, and dust. Mobility, fuel efficiency, and ease of field maintenance are key considerations when evaluating suppliers for these applications.

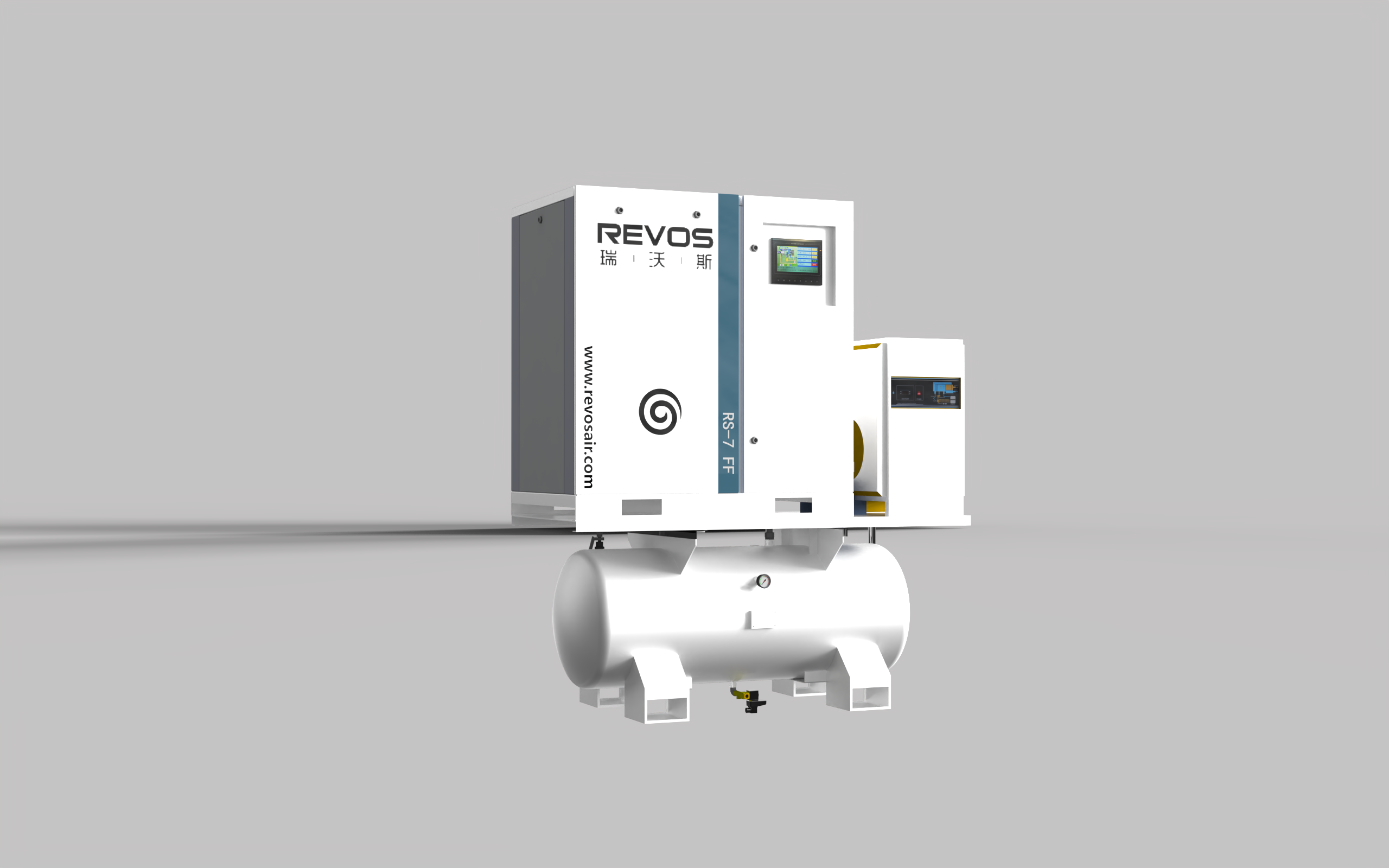

Understanding your industry's specific requirements helps select appropriate screw air compressor technology and evaluate potential suppliers effectively. A supplier with experience in your industry will better understand unique challenges and provide tailored solutions addressing specific needs. When evaluating suppliers like Revos, inquire about their industry experience, request similar customer references, and assess their ability to provide application-specific expertise and support.

Selection Criteria and Implementation Best Practices

Selecting the optimal screw air compressor system involves a systematic approach considering not just the compressor unit but the entire compressed air system—including air treatment, distribution, and control components. Following established best practices throughout selection and implementation maximizes performance, reliability, and energy efficiency of your compressed air system.

Comprehensive Needs Assessment should precede supplier evaluation or technology selection. This involves detailed analysis of compressed air requirements including peak and average flow rates, operating pressure requirements, duty cycle, air quality specifications, and special operating conditions. Consider future expansion plans and potential production process changes affecting air demand. A thorough needs assessment often includes an air audit identifying existing system inefficiencies and providing accurate air consumption pattern data. This data forms the foundation for selecting appropriately sized equipment and avoiding common over-sizing or under-sizing pitfalls.

System Design Optimization extends beyond the compressor to encompass the entire compressed air system. Work with potential suppliers to develop a system design minimizing pressure drops through proper pipe sizing, optimizing air treatment components (dryers, filters, separators) based on specific air quality requirements, and incorporating energy-efficient controls and storage solutions. A well-designed system should include appropriate storage capacity to handle demand fluctuations, prevent frequent compressor cycling, and provide stable air supply during peak demand periods.

Energy Efficiency Evaluation should consider total energy consumption of the entire compressed air system, not just the compressor's rated efficiency. Request detailed energy consumption data from suppliers under various operating conditions, including part-load efficiency that often significantly impacts overall energy costs. Evaluate benefits of variable speed drive technology that adjusts compressor output to match actual demand, typically resulting in substantial energy savings compared to fixed-speed compressors. Inquire about energy management features like automatic sequencing of multiple compressors, load/unload optimization, and sleep modes for low-demand periods. A reputable supplier should provide energy savings calculations based on your specific operating profile and may offer energy performance guarantees or payback period analyses for premium efficiency features.

Installation and Commissioning Best Practices ensure optimal system performance. Work with your selected supplier to develop a detailed installation plan addressing site preparation, utility connections (electrical, cooling water if required), ventilation requirements, and safety considerations. Ensure installation by qualified personnel familiar with screw air compressor requirements. Proper commissioning includes thorough testing of all system components, verification of performance parameters against specifications, and fine-tuning controls for optimal operation. Operator training during commissioning ensures personnel responsible for daily operation and basic maintenance understand system features and requirements.

Preventive Maintenance Planning should be established before compressor installation. Work with your supplier to develop a comprehensive maintenance program based on operating conditions and manufacturer recommendations. This program should include scheduled inspections, lubrication (for oil-injected models), filter replacements, and performance testing. Many modern compressors offer remote monitoring capabilities that can detect potential issues before they result in downtime, allowing for predictive maintenance that maximizes uptime and extends equipment life.

By following these selection criteria and implementation best practices, industrial buyers can ensure they select the optimal screw air compressor system for their specific needs. Taking a comprehensive approach that considers the entire compressed air system rather than just the compressor unit will result in improved efficiency, reliability, and performance, ultimately contributing to enhanced productivity and reduced operating costs. When implemented properly with a trusted partner like Revos, a well-designed screw air compressor system becomes a valuable asset that supports operational excellence for years to come.