In the highly regulated landscape of medical device manufacturing, choosing the right oil-free compressor is a critical decision that directly impacts product quality, regulatory compliance, and operational efficiency. With over a decade of experience implementing compressed air systems in medical facilities, I've witnessed firsthand how compressor selection can either enable seamless production or introduce costly complications in environments requiring absolute air purity.

The implications of subpar compressed air quality extend far beyond equipment performance—they can compromise sterility, contaminate products, and ultimately jeopardize patient safety. As the global medical device market approaches $800 billion by 2030, the demand for reliable, certifiable oil-free compression technology has never been stronger. This guide offers a data-driven framework for evaluating the three primary compressor types—rotary tooth, scroll, and screw—specifically tailored to the unique requirements of medical device manufacturing.

Understanding Medical Device Manufacturing Air Quality Requirements

Medical device manufacturing facilities operate under some of the most stringent air quality standards across all industries. The compressed air utilized in cleanroom operations, product assembly, and packaging must adhere to exacting specifications to ensure patient safety and regulatory compliance.

Regulatory Standards and Certification Requirements

The International Organization for Standardization (ISO) 8573-1:2010 remains the definitive standard for compressed air quality, establishing purity classes for particles, water, and oil contamination. For medical device manufacturing, Class 0 certification for oil contamination is mandatory. This highest purity level requires undetectable oil content (<0.001 mg/m³), which is critical for devices that contact bodily fluids or require sterile packaging.

Medical device manufacturers must also comply with:

- FDA Current Good Manufacturing Practices (cGMP)

- European Medical Device Regulation (MDR)

- ISO 13485 for quality management systems

- NFPA 99 for healthcare facilities (in the United States)

Recent regulatory trends emphasize process validation and continuous monitoring of compressed air systems. While the 2025 updates to medical device standards don't revise ISO 8573-1 itself, they strengthen requirements for documentation and traceability throughout the compressor lifecycle.

Contamination Risks and Consequences

Oil contamination in medical device manufacturing can lead to devastating consequences, including product recalls, regulatory sanctions, and potential harm to patients. Even minute quantities of oil aerosols, vapors, or particulates can:

- Compromise sterile barriers in packaging

- Interfere with bonding and adhesion processes

- Contaminate drug delivery components

- Create biofilm formation risks on implantable devices

A 2024 study in the Journal of Medical Device Manufacturing documented 17 product recalls directly attributed to compressed air contamination over five years, resulting in financial losses exceeding $240 million. These incidents underscore why compromising on air quality can never be justified in this industry.

Comparative Analysis of Oil-Free Compressor Technologies

Selecting the optimal oil-free compressor requires a thorough understanding of the capabilities, limitations, and performance characteristics of available technologies. For medical device manufacturing, three types dominate the market: rotary tooth, scroll, and screw compressors. Each offers distinct advantages depending on specific application requirements.

Rotary Tooth Compressors

Rotary tooth compressors, often referred to as rotary vane compressors, utilize a slotted rotor with vanes that slide in and out to compress air within a cylindrical chamber. This technology offers several advantages for medical device manufacturing applications:

Technical Specifications:

- Typical flow rates: 0.5-15 m³/min

- Pressure range: 7-10 bar(g)

- Noise levels: 65-75 dB(A)

- Energy efficiency: Moderate (typically 6-8 kW/100 cfm)

Advantages:

- Compact footprint ideal for facilities with limited space

- Lower initial capital investment than other technologies

- Excellent performance at partial loads, suitable for variable demand

- Fewer moving parts than screw compressors, potentially reducing maintenance complexity

Limitations:

- Higher maintenance requirements than scroll compressors due to vane wear

- Limited maximum flow capacity may restrict use in large-scale production

- Susceptible to performance degradation in high-temperature environments

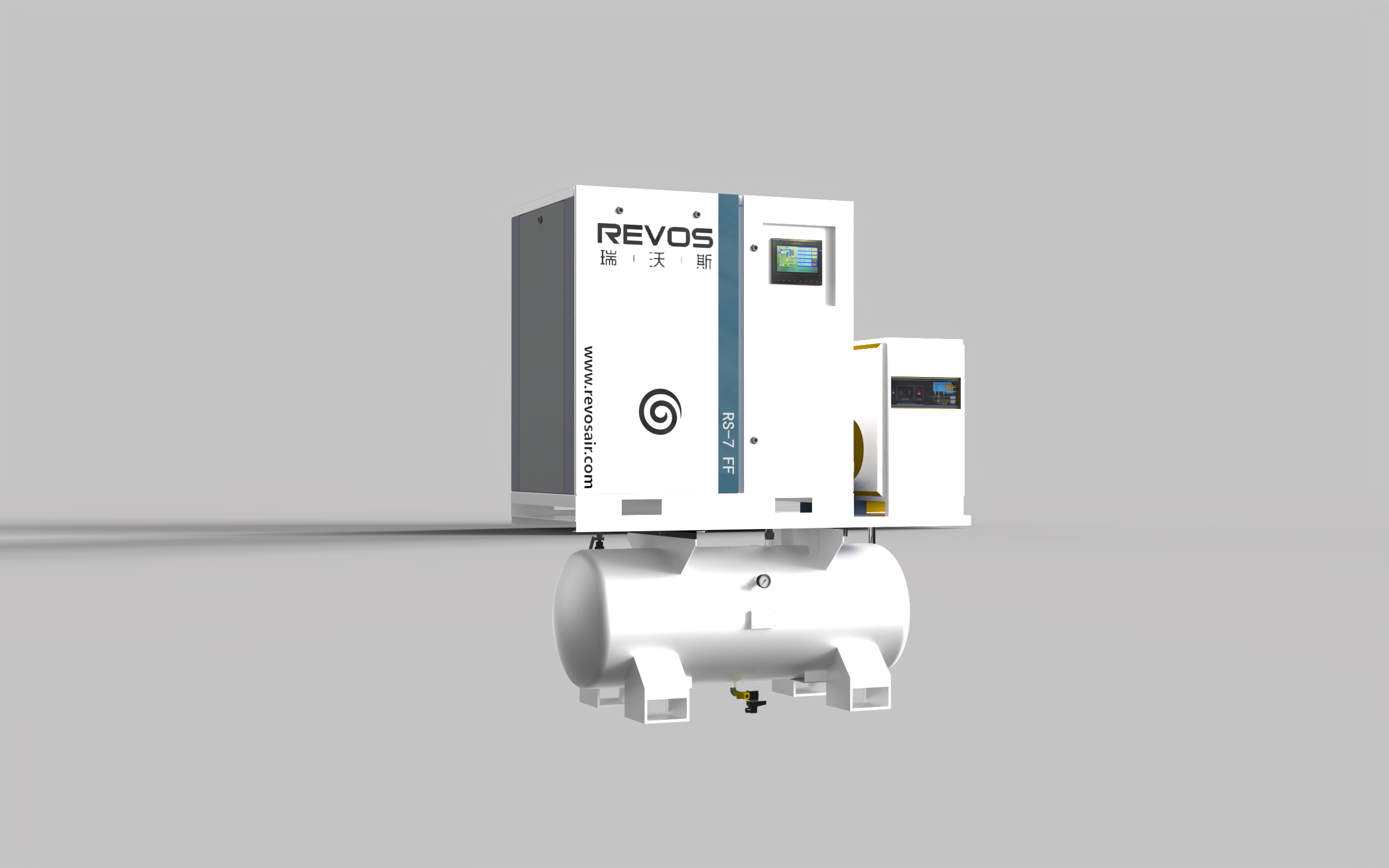

Ideal Applications: Small to medium production lines, laboratory settings, and applications with variable air demand profiles. When evaluating rotary tooth compressors suppliers, look for manufacturers like Revos that have developed specialized models achieving ISO 8573-1 Class 0 certification while maintaining competitive energy consumption levels.

Scroll Type Air Compressors

Scroll compressor technology employs two interleaving spiral elements—one stationary and one orbiting—to compress air progressively without metal-to-metal contact. This innovative design has gained significant traction in medical manufacturing environments:

Technical Specifications:

- Typical flow rates: 0.3-25 m³/min

- Pressure range: 7-13 bar(g)

- Noise levels: 55-65 dB(A) (among the lowest available)

- Energy efficiency: High (typically 5.5-7 kW/100 cfm)

Advantages:

- Exceptionally low noise and vibration levels, critical for cleanroom environments

- Fewer wearing parts than rotary or screw designs, reducing maintenance requirements

- Excellent oil-free performance with inherent design features preventing contamination

- High reliability with mean time between failures (MTBF) often exceeding 40,000 hours

Limitations:

- Higher initial cost than rotary compressors

- Less efficient at very high flow rates compared to screw compressors

- Sensitivity to particulate contamination requiring robust pre-filtration

Ideal Applications: Precision manufacturing processes, cleanrooms, and environments where noise reduction is a priority. The Atlas Copco SF-MED series exemplifies modern scroll technology optimized for medical applications, featuring integrated drying systems and advanced filtration to ensure Class 0 air quality.

Screw Air Compressors

Screw compressors utilize two intermeshing helical rotors to compress air continuously, offering high flow rates and robust performance characteristics suitable for demanding applications:

Technical Specifications:

- Typical flow rates: 5-100+ m³/min

- Pressure range: 7-15 bar(g)

- Noise levels: 70-85 dB(A)

- Energy efficiency: Excellent for large systems (typically 5-6.5 kW/100 cfm)

Advantages:

- Highest flow capacity for large-scale manufacturing operations

- Superior energy efficiency at full load, beneficial for continuous production

- Robust construction suitable for demanding industrial environments

- Modular configurations available for redundancy and scalability

Limitations:

- Largest footprint requiring significant installation space

- Higher initial investment, though offset by lower lifecycle costs for large systems

- More complex maintenance requiring specialized technicians

Ideal Applications: High-volume production facilities, centralized air systems serving multiple processes, and applications requiring continuous operation. When evaluating screw air compressors suppliers, consider companies like Dürr Technik that have developed specialized models for medical applications featuring water-injected compression chambers that eliminate any risk of oil contamination.

Comparative Performance Analysis

To illustrate practical differences between these technologies, consider a medium-sized medical device manufacturing facility requiring 15 m³/min of compressed air at 8 bar(g):

| Performance Metric | Rotary Tooth | Scroll | Screw |

|-------------------|--------------|--------|-------|

| Energy Consumption (kWh/year) | 78,000 | 72,000 | 65,000 |

| Maintenance Cost ($/year) | $4,500 | $3,200 | $3,800 |

| Noise Level (dB(A)) | 72 | 62 | 78 |

| Floor Space (m²) | 4.5 | 5.2 | 8.7 |

| Initial Investment ($) | $45,000 | $62,000 | $85,000 |

| Estimated Lifespan (years) | 8-10 | 10-12 | 12-15 |

Note: Based on 8,000 operating hours/year and industry average energy costs.

This oil-free compressor technology comparison demonstrates the classic trade-off between initial investment and long-term operating costs. While rotary tooth compressors offer the lowest upfront cost, scroll and screw technologies typically provide better lifecycle economics through improved energy efficiency and reduced maintenance requirements.

Supplier Evaluation Criteria for Medical Device Manufacturers

Selecting the right oil-free compressor supplier matters as much as choosing the appropriate technology. Medical device manufacturers must hold suppliers to rigorous standards that align with regulatory requirements and quality management systems. Based on industry best practices developed through years of supplier qualification experience, the following evaluation framework provides a comprehensive approach to supplier assessment.

Certification and Regulatory Compliance

Essential Certifications:

- ISO 8573-1 Class 0 certification for oil-free air purity

- ISO 13485 compliance for medical device manufacturing processes

- CE marking demonstrating compliance with European medical device directives

- FDA registration as a medical device component supplier where applicable

Documentation Requirements:

- Validated performance qualification protocols specific to medical applications

- Comprehensive quality management system documentation

- Traceability records for critical components

- Calibration and validation procedures for all monitoring systems

Technical Capabilities and Innovation

Technology Assessment:

- Engineering expertise in medical-grade compressed air systems

- Commitment to research and development, demonstrated through patent portfolio

- Ability to customize solutions for specific manufacturing processes

- Integration capabilities with facility monitoring and control systems

Innovation Trajectory:

- Recent technological advancements (last 2-3 years)

- Roadmap for future developments in energy efficiency and air quality

- Investment in digitalization and Industry 4.0 capabilities

- Development of predictive maintenance technologies

Quality Management and Reliability

Quality System Assessment:

- Supplier's internal quality control processes

- Incoming material inspection protocols

- Manufacturing process controls and validation

- Finished product testing procedures

Reliability Metrics:

- Mean time between failures (MTBF) data specific to medical applications

- Warranty coverage and response time commitments

- Spare parts availability and lead times

- Field failure analysis and corrective action processes

Service and Support Capabilities

Support Infrastructure:

- Geographic proximity of service centers to manufacturing facilities

- Availability of factory-trained service technicians with medical device experience

- Emergency response time guarantees (critical for continuous processes)

- Remote monitoring and diagnostic capabilities

Training and Knowledge Transfer:

- Operator training programs specific to medical applications

- Maintenance technician certification options

- Documentation and training materials compliant with regulatory requirements

- Ongoing educational resources for regulatory updates

Total Cost of Ownership Analysis

While initial purchase price matters, medical device manufacturers should evaluate suppliers based on total cost of ownership (TCO) over a typical 10-year lifecycle:

TCO Components:

- Initial capital investment

- Installation and commissioning costs

- Energy consumption (typically 70-80% of TCO)

- Maintenance parts and labor

- Filter and consumable replacement

- Downtime costs

- Decommissioning and disposal

For example, a scroll compressor with higher initial investment but lower energy consumption may provide 15-20% lower TCO over 10 years compared to a rotary tooth compressor with lower purchase price. Industry data suggests medical device manufacturers who conduct thorough TCO analyses achieve 12-18% lower compressed air system costs over equipment lifecycle.

Selection Process and Decision Framework

Selecting the optimal oil-free compressor for medical device manufacturing requires a systematic approach balancing technical requirements, regulatory compliance, and economic considerations. Based on years of practical experience implementing compressed air systems in medical facilities, the following step-by-step framework provides a structured methodology for making this critical decision.

Needs Assessment and Requirements Definition

The foundation of any successful compressor selection is a clear understanding of specific application requirements. This phase should engage cross-functional teams including manufacturing, quality, engineering, and regulatory affairs:

Key Requirements to Document:

- Air Quality Specifications: Define required ISO 8573-1 purity class for particles, water, and oil, considering the most sensitive manufacturing process

- Flow Requirements: Calculate peak and average demand, including future expansion plans (typically adding 20-30% capacity)

- Pressure Requirements: Determine minimum and maximum operating pressure, accounting for pressure drops throughout the distribution system

- Reliability Needs: Establish availability requirements, considering the impact of downtime on production schedules

- Facility Constraints: Document space limitations, noise restrictions, utility availability, and environmental conditions

A comprehensive needs assessment should result in a detailed compressed air specification document that serves as the basis for evaluating both technologies and suppliers.

Technology Evaluation and Selection

With clear requirements defined, the next step involves matching those needs to the appropriate compressor technology using a structured decision matrix that weights key factors according to facility-specific priorities.

Supplier Evaluation and Qualification

Once optimal technology has been identified, focus shifts to selecting a qualified supplier through a rigorous qualification process that includes Request for Information (RFI), detailed supplier questionnaires, site visits, reference checks, and technical presentations.

Pilot Testing and Validation

Before committing to full-scale implementation, consider conducting a pilot test with the selected technology and supplier to verify performance under actual operating conditions.

Implementation Planning

The final step involves developing a comprehensive implementation plan addressing timeline, resource allocation, budget, quality control, training, documentation, commissioning, and contingency planning to ensure smooth transition to the new compressed air system.

Emerging Trends and Future Developments

The field of oil-free compression technology continuously evolves to meet increasing demands of medical device manufacturing. Staying informed about emerging trends helps make strategic long-term decisions that keep facilities at the forefront of technology while ensuring regulatory compliance and operational efficiency.

Technological Advancements

Material Science Innovations: Recent developments in composite materials are revolutionizing oil-free compressor design. Advanced carbon-fiber reinforced polymers and ceramic coatings create components with superior wear resistance and reduced friction, eliminating the need for lubrication while extending service life.

IoT Integration and Smart Monitoring: Integration of Internet of Things (IoT) technology allows real-time monitoring of key performance indicators and predictive maintenance capabilities, providing valuable data analytics for regulatory compliance documentation and process optimization.

Energy Recovery Systems: New designs incorporate advanced energy recovery technologies that capture and repurpose waste heat generated during compression, reducing overall facility energy consumption by 15-20% in some cases.

By carefully considering both current requirements and future trends, medical device manufacturers can select oil-free compressor systems that not only meet today's regulatory requirements but also provide a foundation for future growth and innovation in this critical industry sector.