In the food processing industry, where product safety and regulatory compliance are non-negotiable priorities, selecting the right oil-free compressor system represents a critical decision with far-reaching implications for operational efficiency, product quality, and long-term profitability. Compressed air serves as a vital utility in food manufacturing, often contacting products directly or indirectly across applications ranging from pneumatic conveying and mixing to packaging and aseptic processing. This reality demands complete elimination of contamination risk. This technical guide provides food processing professionals with a systematic framework for evaluating and selecting oil-free compressors that meet the stringent requirements of modern food manufacturing environments.

The global market for oil-free compressors in food processing is projected to grow at a 6.6% compound annual growth rate (CAGR) from 2025 to 2035, reflecting the industry's recognition that oil-free compressed air has evolved from an optional upgrade to an essential investment in product integrity and brand protection.

Understanding Oil-Free Compressor Technologies for Food Processing

The foundation of effective compressor selection lies in understanding the available oil-free technologies and their suitability for specific food processing applications. Three primary technologies dominate today's market, each presenting distinct advantages and limitations that must be carefully evaluated against production requirements, space constraints, and performance expectations.

Scroll Type Air Compressors

Scroll compressors have gained significant traction in food processing facilities due to their inherently oil-free operation and compact design characteristics. This technology utilizes two interleaving spiral elements—one fixed and one orbiting—to compress air without requiring oil lubrication within the compression chamber. This design offers several benefits particularly valuable in food processing environments:

Key Advantages:

- Superior air quality: The absence of oil in the compression chamber enables scroll compressors to achieve ISO 8573-1 Class 0 certification for oil content, ensuring zero risk of product contamination.

- Quiet operation: Typically operating at 60-75 dB(A), scroll compressors excel in facilities where noise reduction is prioritized, especially near packaging lines, quality control stations, and employee work areas.

- Compact footprint: Their space-efficient design accommodates facilities with limited equipment room space, offering flexible installation options including wall-mounted configurations.

- Reduced maintenance requirements: With fewer moving parts than screw compressors, scroll models generally require less frequent maintenance, minimizing production downtime.

Considerations:

- Capacity limitations: Scroll compressors perform optimally in applications requiring 1-30 hp, making them ideal for small to medium production lines but potentially insufficient for large-scale operations.

- Heat generation: While all compressors produce heat during operation, scroll units tend to have higher discharge temperatures, necessitating proper ventilation or heat recovery systems.

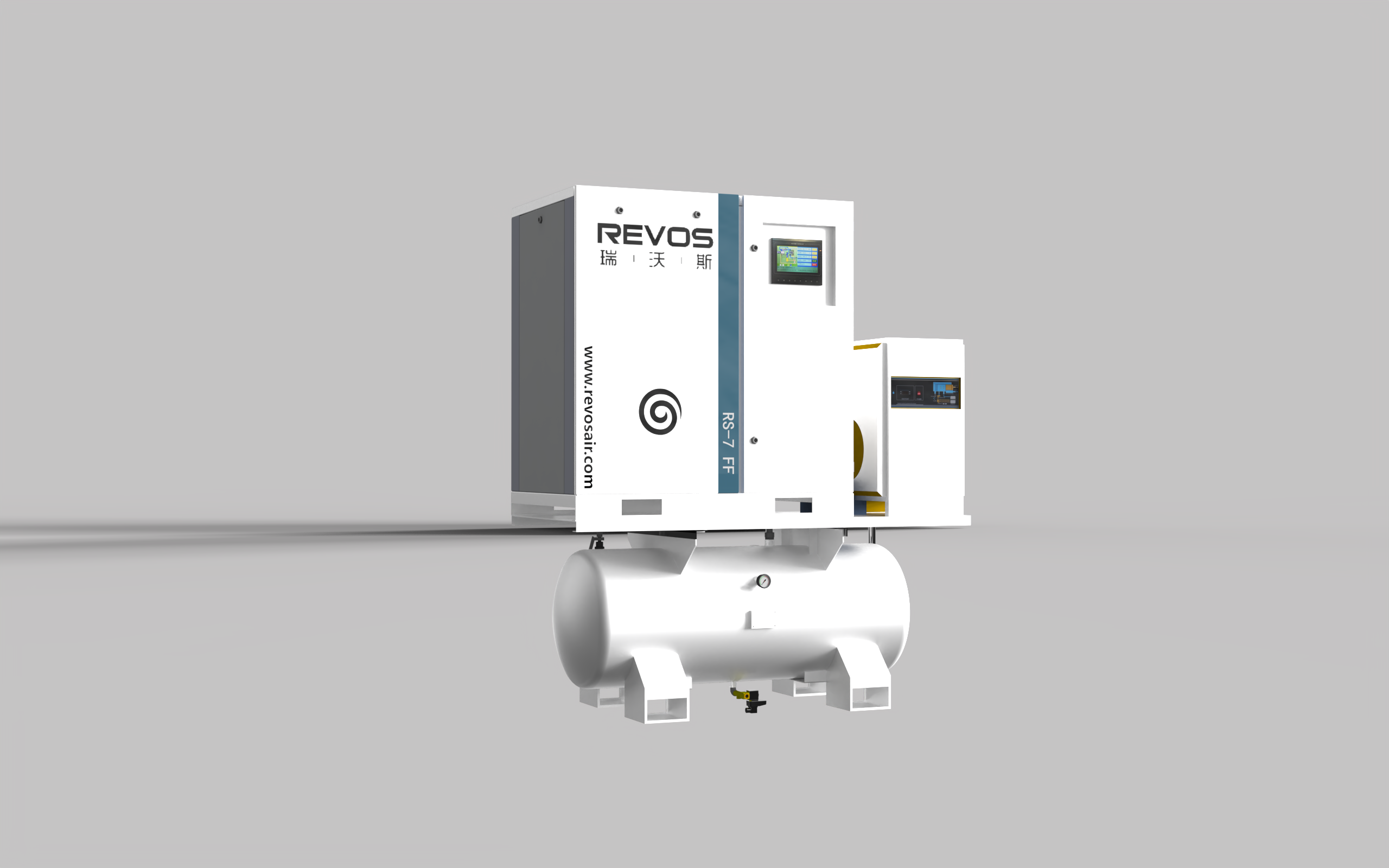

Innovations in scroll technology continue to expand its applicability in food processing. Revos, a leading innovator in oil-free compressor technology, achieved a breakthrough in scroll tooth compressor design in 2022, followed by German TÜV Class 0 certification in 2023. This advancement has made scroll type air compressors viable even for demanding food processing applications requiring the highest air purity standards.

Screw Compressor Technology

Screw compressors, available in both oil-injected and oil-free configurations, have long served as industrial workhorses in manufacturing environments. Oil-free screw models utilize water or specialized polymers for lubrication and cooling, eliminating the risk of oil contamination and making them suitable for food processing environments where product purity is paramount.

Key Advantages:

- High capacity range: Oil-free screw compressors excel in large-scale operations, offering capacities from 20 hp up to several hundred horsepower, making them well-suited for centralized compressed air systems serving multiple production lines.

- Energy efficiency: Two-stage oil-free screw compressors deliver impressive energy efficiency, particularly when equipped with variable speed drives (VSD) that match output to real-time demand.

- Continuous operation capability: Designed for 24/7 operation, screw compressors provide reliable performance in the continuous production environments common to food manufacturing facilities.

- Superior pressure capabilities: These compressors can consistently deliver higher pressures than scroll models, accommodating applications requiring pressures above 150 psi.

Considerations:

- Complex maintenance requirements: The precision components and cooling systems in oil-free screw compressors demand specialized maintenance expertise and more frequent service intervals compared to scroll technology.

- Higher initial investment: While offering excellent long-term value through efficiency and durability, oil-free screw compressors typically require a higher upfront investment than scroll technology.

- Installation considerations: Their larger size and weight necessitate dedicated floor space and may require specialized structural and utility considerations during installation.

Recent innovations in screw compressor technology—such as Atlas Copco's ZR 200-315 VSD models introduced in July 2025—have improved flow rates by up to 14% and overall efficiency by 7%, further solidifying screw compressor technology as a leading choice for large-scale food processing facilities seeking reliable, high-capacity oil-free air solutions.

Rotary Tooth Compression Mechanism

Rotary tooth compressors represent a specialized category of oil-free technology that combines advantageous elements of both screw and scroll designs. These compressors utilize two intermeshing tooth-shaped rotors to compress air without oil lubrication in the compression chamber, offering unique benefits for specific food processing applications.

Key Advantages:

- Certifiable oil-free design: The complete isolation of the compression chamber from any lubrication system ensures Class 0 air quality suitable for the most demanding direct food contact applications.

- Exceptional energy efficiency: Optimized rotor profiles minimize internal leakage and pressure losses, resulting in excellent energy efficiency—particularly at partial loads common in food processing operations with variable demand.

- Low noise operation: The meshing rotors create a smooth compression cycle with reduced vibration and noise levels compared to traditional screw compressors, contributing to improved workplace conditions.

- Enhanced durability: With fewer wearing parts and robust construction, rotary tooth compressors offer extended service life in demanding production environments with minimal downtime.

Considerations:

- Limited application range: These specialized compressors are typically most cost-effective in medium-capacity applications (30-150 hp), filling a niche between scroll and screw technologies.

- Availability considerations: Rotary tooth compressors may have longer lead times and require specialized service expertise compared to more common compressor technologies.

In 2025, the industry celebrates 45 years of rotary tooth technology, which has evolved from a niche solution to a mainstream option for food processors seeking reliable, oil-free compressed air. The technology continues gaining acceptance in applications from dairy processing to baked goods production, where air quality and energy efficiency are paramount concerns.

Critical Selection Criteria for Food Processing Applications

Selecting the optimal oil-free compressor involves evaluating multiple factors beyond basic technology type. The following criteria directly impact operational performance, regulatory compliance, and total cost of ownership, and should be carefully weighted according to specific application requirements.

Air Quality Requirements and Certification Standards

Air quality stands as the most critical factor in food processing applications, where compressed air often contacts edible products or packaging materials directly. The International Organization for Standardization (ISO) 8573-1 standard classifies compressed air quality based on three primary contaminants: solid particles, water, and oil—with oil contamination presenting the most significant risk to product safety.

ISO 8573-1 Class 0 Certification:

- Represents the highest air purity level with no detectable oil content in the compressed air stream

- Requires rigorous testing and documentation by accredited certification bodies to verify performance

- Mandatory for applications involving direct food contact or pharmaceutical production

- Provides critical protection against product recalls and brand damage from contamination incidents

Complementary Standards:

- ISO 22000: Food safety management system certification that integrates with compressed air quality requirements

- FDA 21 CFR Part 110: Current Good Manufacturing Practices (cGMP) for food processing facilities

- EC 10/2011: European regulation on plastic materials and articles intended to contact food

The dairy industry exemplifies the critical nature of air quality standards, where applications like milk agitation, pneumatic valve operation, and packaging require Class 0 air to prevent product contamination and ensure consumer safety. Even trace oil contamination can compromise product quality, introduce off-flavors, and create serious food safety hazards.

Energy Efficiency and Regulatory Compliance

Energy costs represent a significant portion of a compressor's total cost of ownership—often exceeding the initial purchase price within 2-3 years of operation. As such, energy efficiency has become a primary selection criterion for food processors seeking to optimize operational costs while reducing environmental impact.

Efficiency Standards:

- IE3/IE4 Motor Standards: The International Electrotechnical Commission (IEC) 60034-30 standard defines efficiency classes for electric motors, with IE3 (Premium Efficiency) and IE4 (Super Premium Efficiency) representing the highest levels mandated for new installations in many regions.

- EU Regulations: As of July 2023, the EU requires IE4 efficiency for motors between 75-200 kW, with expanded requirements phasing in through 2025.

- DOE Standards: The U.S. Department of Energy implemented new efficiency regulations for oil-flooded rotary compressors starting January 10, 2025, with similar standards for oil-free models currently under development.

Energy-Saving Technologies:

- Variable Speed Drives (VSD): Adjust motor speed to precisely match air demand, typically reducing energy consumption by 20-35% compared to fixed-speed compressors in applications with variable demand profiles.

- Heat Recovery Systems: Capture waste heat from compression for facility heating, water heating, or process applications, providing additional energy savings of 70-90% of the compressor's input energy.

- Smart Controls: Advanced control systems optimize compressor operation, coordinate multiple units in a system, and provide real-time energy consumption data for continuous improvement initiatives.

These technologies not only reduce operational costs but also support sustainability initiatives and corporate social responsibility goals that are increasingly important to consumers and stakeholders in the food industry.

Maintenance Requirements and Hygienic Design

Food processing environments demand equipment that maintains performance while withstanding rigorous cleaning protocols and minimizing contamination risks. Compressor maintenance represents both a critical operational consideration and a potential source of downtime if not properly managed.

Hygienic Design Features:

- Stainless Steel Construction: Critical components contacting compressed air should utilize stainless steel to prevent corrosion and bacterial growth in humid environments.

- Sealed Enclosures: Protect internal components from dust, moisture, and cleaning chemicals common in food processing environments.

- Tool-Free Access: Design features facilitating inspection and maintenance without compromising air quality or requiring extensive disassembly.

- Sanitary Air Intake: Properly filtered and strategically positioned intake systems prevent contamination from facility dust, odors, or airborne pathogens.

Maintenance Best Practices:

- Preventive Maintenance Schedules: Regular inspection and replacement of filters, separators, and lubricants based on manufacturer recommendations and actual operational conditions.

- Comprehensive Documentation: Detailed record-keeping of all maintenance activities to demonstrate compliance with regulatory requirements and quality management systems.

- Specialized Training: Ensure maintenance personnel receive specialized training on oil-free compressor systems and food safety protocols to prevent contamination during service.

- Service Contracts: Consider manufacturer or third-party service agreements to ensure access to specialized expertise and genuine replacement parts.

These maintenance practices ensure regulatory compliance while contributing to extended equipment life and optimized performance, directly impacting total cost of ownership and operational reliability.

Total Cost of Ownership Analysis

While initial purchase price naturally influences equipment selection decisions, total cost of ownership (TCO) analysis provides a more accurate assessment of a compressor's long-term value. TCO encompasses three primary cost components: acquisition costs, operational costs, and maintenance costs, with operational costs typically dominating over the equipment lifecycle.

Acquisition Costs:

- Purchase price of the compressor unit

- Installation and commissioning expenses

- Required ancillary equipment (dryers, filters, receivers)

- Electrical and piping modifications

- Training for operators and maintenance personnel

Operational Costs:

- Energy consumption (typically 70-80% of TCO over a 10-year lifecycle)

- Utility costs for cooling water (if applicable)

- Space requirements and associated facility costs

- Filter and consumable replacements

- Energy losses from pressure drops in the distribution system

Maintenance Costs:

- Preventive maintenance contracts

- Replacement parts and labor

- Unscheduled downtime and associated production losses

- Calibration and certification expenses

- End-of-life disposal or recycling costs

TCO Optimization Strategies:

- Right-sizing: Selecting a compressor with appropriate capacity to avoid energy waste from oversized units or inefficiency from undersized equipment operating at full load continuously.

- Energy Efficiency: Investing in premium efficiency motors (IE4) and variable speed drives to match air production with demand patterns.

- Heat Recovery: Implementing systems to capture and utilize waste heat for facility heating, water heating, or process applications.

- Predictive Maintenance: Utilizing condition monitoring and predictive analytics to identify potential issues before they result in unplanned downtime.

A comprehensive TCO analysis typically reveals energy consumption as the single largest cost component, often exceeding the initial purchase price within the first two years of operation. This underscores the importance of prioritizing energy efficiency when selecting oil-free compressors for food processing applications.

Emerging Trends and Technological Innovations

The oil-free compressor market continues to evolve rapidly, driven by advancements in materials science, control systems, and increasing demands for higher efficiency and improved air quality. Several key trends are shaping the industry in 2025 and beyond, influencing equipment design and selection criteria for forward-thinking food processors.

Internet of Things (IoT) Integration and Smart Monitoring

IoT technology has transformed compressor management from reactive to proactive maintenance, offering significant benefits for food processing facilities seeking to optimize reliability and efficiency.

IoT-Enabled Capabilities:

- Real-time Performance Monitoring: Continuous tracking of key operating parameters like discharge pressure, temperature, energy consumption, and air flow.

- Predictive Maintenance: Advanced algorithms analyze performance data to identify potential issues before equipment failure or quality issues occur.

- Remote Diagnostics: Manufacturer access to operational data for troubleshooting and optimization without requiring on-site visits.

- Energy Management: Detailed energy consumption analysis and optimization recommendations based on actual operating patterns.

- Integration with SCADA Systems: Seamless connectivity with facility-wide control systems for coordinated operation and comprehensive data analysis.

Reported Benefits:

- 15-20% reduction in energy consumption through optimized operation

- 30-40% reduction in unplanned downtime through predictive maintenance

- Improved air quality consistency and simplified compliance documentation

- Enhanced troubleshooting capabilities and reduced service response times

- Data-driven decision making for system optimization and expansion planning

Case studies from food processing facilities implementing IoT-enabled compressor systems demonstrate payback periods as short as 12-18 months, primarily through energy savings and reduced maintenance costs.

Sustainability and Environmental Considerations

As environmental sustainability becomes increasingly important to corporate responsibility initiatives and consumer expectations, food processors are evaluating their compressed air systems' environmental impact alongside traditional performance metrics.

Sustainability Features:

- Energy Efficiency: High-efficiency compressors and drive systems that minimize energy consumption and associated carbon emissions.

- Heat Recovery: Systems capturing and repurposing waste heat from compression for facility heating, water heating, or process applications.

- Low Noise Emissions: Reduced noise pollution for improved working conditions and community relations.

- Refrigerant-Free Drying: Adsorption dryers eliminating the need for ozone-depleting refrigerants in compressed air treatment.

- Eco-Friendly Materials: Use of recyclable materials and environmentally responsible manufacturing processes.

Sustainability Certifications:

- ISO 14001: Environmental management system certification

- LEED: Leadership in Energy and Environmental Design for facility construction and operation

- Energy Star: Certification for energy-efficient equipment meeting strict efficiency guidelines

- FSSC 22000: Food Safety System Certification integrating environmental management principles

These sustainability initiatives not only reduce environmental footprint but also improve operational efficiency and reduce costs, creating a win-win scenario for processors and the environment.

Compliance with Evolving Regulatory Standards

The regulatory landscape for food processing continues to evolve, with increasingly stringent requirements for food safety, worker safety, and environmental protection. Compressed air systems play a critical role in meeting these requirements, making compliance a key consideration in compressor selection and operation.

Key Regulatory Considerations:

- Food Safety Modernization Act (FSMA): Requires comprehensive food safety systems, including controls for potential contamination sources like compressed air.

- Occupational Safety and Health Administration (OSHA): Establishes limits for noise exposure, electrical safety, and machine guarding applicable to compressor installations.

- National Electrical Code (NEC): Specifies requirements for electrical installations in hazardous locations, relevant for compressors near flammable materials.

- European Union Regulations: Includes CE marking requirements, RoHS compliance for electrical components, and REACH for chemical usage.

- Local Environmental Regulations: May include restrictions on noise levels, emissions, water usage, and waste disposal.

Compliance Strategies:

- Regulatory Assessment: Conducting a comprehensive review of applicable regulations for specific food products and geographic locations of operation.

- Documentation: Maintaining detailed records of compressor performance, maintenance activities, and air quality testing to demonstrate compliance.

- Training: Ensuring all personnel involved in compressor operation and maintenance receive appropriate training on regulatory requirements and company procedures.

- Third-Party Audits: Scheduling regular independent audits to verify compliance and identify potential areas for improvement.

- Future-Proofing: Selecting equipment and systems designed to accommodate anticipated regulatory changes, particularly in energy efficiency and environmental impact areas.

By incorporating these compliance strategies into compressor selection and management practices, food processors can minimize regulatory risks while ensuring product safety and quality.

Application-Specific Considerations

Different food processing industry segments present unique challenges and requirements for compressed air systems. Understanding these application-specific considerations ensures optimal compressor selection and system design for maximum performance, compliance, and efficiency.

Dairy Processing Requirements

Dairy processing represents one of the most demanding applications for compressed air systems, with direct contact between compressed air and sensitive products occurring at multiple production stages.

Critical Considerations:

- Air Quality: Class 0 oil-free air is mandatory for applications like milk agitation, cheese production, and yogurt fermentation to prevent product contamination and off-flavors that could compromise product quality and safety.

- Moisture Control: Dairy environments require rigorous moisture removal to prevent bacterial growth in compressed air lines and ensure product quality throughout production and packaging processes.

- Hygienic Design: Compressors and air treatment components must feature stainless steel construction and sanitary connections to withstand frequent washdowns and maintain aseptic conditions.

- Energy Efficiency: With 24/7 operation common in dairy processing, energy-efficient compressors with heat recovery systems offer significant operational cost advantages while reducing environmental impact.

By carefully evaluating these technology options and selection criteria, food processing professionals can make informed decisions that balance air quality requirements,